Alignment Diagnostics & Tire Wear Analysis in Lakewood, WA

Get accurate alignment diagnostics and detailed tire wear analysis for semi-trucks, heavy-duty trucks, and commercial fleet vehicles. At Expedited Truck Alignment and Tires, we identify the root cause of alignment issues—not just the symptoms—to restore proper handling, stability, and tire life.

What We Offer for Your Truck’s Alignment & Tire Wear Issues

Misalignment can cause severe tire damage, unstable steering, vibration, and decreased fuel efficiency. Our alignment diagnostic service uses precise measurement techniques to identify tracking issues, axle offset, thrust angle misalignment, and suspension-related wear patterns.

We analyze tire wear indicators such as cupping, feathering, shoulder wear, and scalloping to determine the exact mechanical issue causing the problem. Whether your truck is pulling, vibrating, or wearing through tires faster than normal, we provide a complete diagnostic report and recommended correction.

Our team works with semi-trucks, box trucks, heavy-duty vehicles, and full commercial fleets to prevent costly tire failure and improve long-term reliability.

Why Choose Professional Diagnostics & Tire Wear Analysis

Accurate diagnostics are essential before performing any alignment correction. Unlike basic tire checks, our analysis identifies the underlying mechanical cause—whether it’s worn bushings, incorrect thrust angle, axle skew, or steering system issues.

We evaluate:

Tire cupping, feathering, ridging & scalloping

Camber, toe, thrust angle & axle position

Weight distribution & suspension wear

Front & rear tracking differences

Axles affected by suspension wear or repairs

Steering response & vibration patterns

Proper diagnosis ensures your alignment is corrected the right way the first time, saving you thousands in unnecessary tire replacement costs.

Frequently Asked Questions

Question 1: What are the common signs of tire wear caused by misalignment?

Feathering, cupping, inside/outside wear, vibration, uneven shoulder wear, or steering pull.

Question 2: How often should tire wear and alignment be inspected?

Every 20,000–30,000 miles or during routine maintenance, depending on service conditions.

Question 3: Can tire wear patterns determine the exact alignment issue?

Yes. Each wear pattern is linked to specific mechanical problems such as camber, toe, or thrust angle issues.

Question 4: Will diagnostics identify suspension problems?

Yes. We often detect worn shocks, bushings, kingpins, or steering components during analysis.

Precision Equipment. Expert Technicians.

State-of-the-art alignment technology for accurate results every time

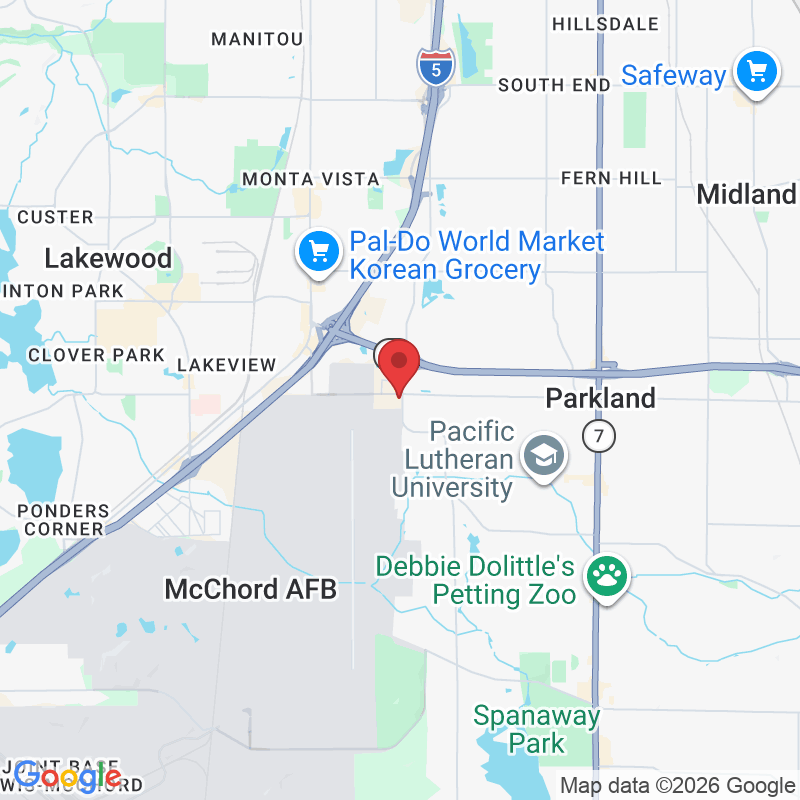

Our Service Area

Contact Us Today

Schedule your appointment today and experience expert truck tire and alignment services!