Kingpin, Bushing & Steering Joint Replacement in Lakewood, WA

Restore proper steering control, stability, and safety with professional kingpin, bushing, and steering joint replacement services for semi-trucks, heavy-duty trucks, and commercial fleets. Expedited Truck Alignment and Tires provides accurate diagnostics and dependable component replacement to keep your truck steering straight and performing at its best.

What We Offer for Kingpin, Bushing & Steering Joint Replacement

Worn kingpins, bushings, and steering joints can drastically affect steering response, tracking, and truck stability—especially under heavy loads. Symptoms like loose steering, uneven tire wear, vibration, popping noises, or poor control often indicate your steering components are failing.

Our technicians specialize in identifying worn components and performing precise replacements using high-quality parts engineered for heavy-duty use. We service steer axles, kingpins, tie rods, drag links, bushings, steering knuckles, and suspension-related steering linkages.

Whether your truck is wandering, pulling to one side, fighting turns, or showing signs of progressive tire wear, we diagnose the root cause and replace the failing components. From local fleets to long-haul operators, our replacement services help restore proper alignment, reduce wear on suspension parts, and improve overall driving performance.

Why Choose Expedited Truck Alignment for Steering Component Replacement

Your truck’s steering system must operate precisely to ensure safe braking, lane control, and predictable handling. Worn kingpins or steering joints can quickly lead to misalignment issues, uneven tire wear, suspension stress, and unsafe driving conditions.

At Expedited Truck Alignment and Tires, we take a diagnostic-first approach—inspecting steering geometry, bushings, kingpin play, and joint integrity before performing any replacement. This ensures the repair is accurate, long-lasting, and fully compatible with heavy-duty operation.

Our customers choose us because:

We diagnose steering & kingpin wear with precision

We replace worn kingpins, bushings & joints using heavy-duty components

We correct alignment after component replacement

We eliminate steering play, vibration & drift

Our replacement services help prevent steering failures, extend component life, and eliminate premature tire wear.

Frequently Asked Questions

Question 1: How do I know if my kingpins need replacement?

Clicking noises, loose steering, wandering, uneven tire wear, and poor return-to-center are common signs.

Question 2: What causes kingpin or bushing wear?

Heavy loads, lack of lubrication, road impact, corrosion, and long-term mileage can accelerate wear.

Question 3: Do you realign the truck after replacing steering components?

Yes — alignment is required after kingpin, joint, or bushing replacement to ensure proper tracking.

Question 4: Can worn steering joints damage tires?

Yes. Bad joints cause irregular steering angles, leading to cupping, feathering, and rapid tire wear.

Precision Equipment. Expert Technicians.

State-of-the-art alignment technology for accurate results every time

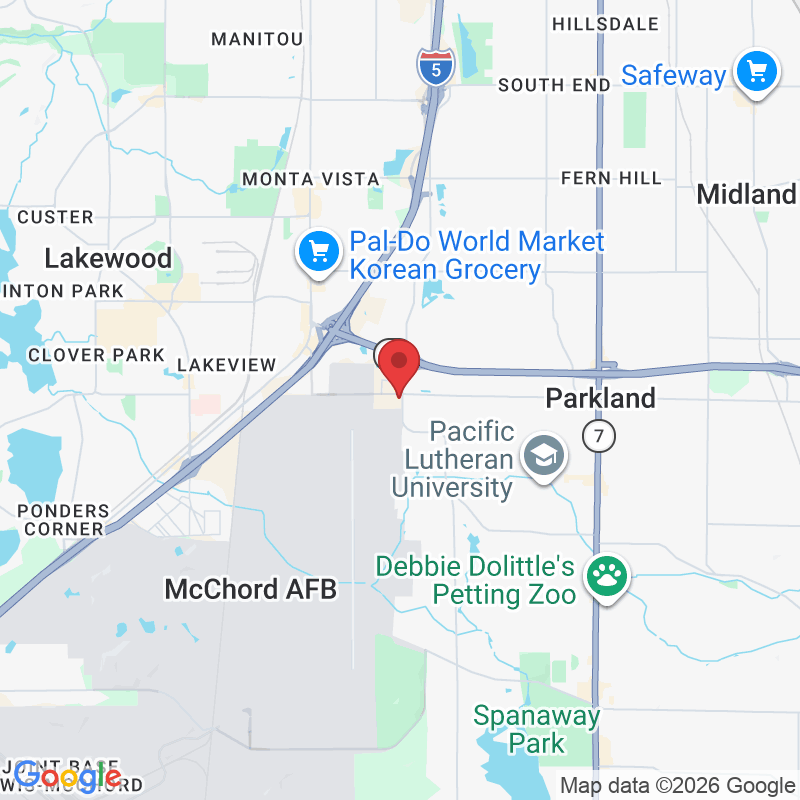

Our Service Area

Contact Us Today

Schedule your appointment today and experience expert truck tire and alignment services!