Frequently Asked Questions

Your trusted resource for clear, helpful answers about alignment, suspension, tire services, and mobile on-site support for semi-trucks, heavy-duty trucks, and commercial fleets.

Truck Alignment FAQs

1. How do I know if my truck needs alignment?

Common signs include drifting or pulling, uneven tire wear, vibration at higher speeds, unstable steering, or the steering wheel being off-center.

2. How often should I get my truck aligned?

Most semi-trucks need alignment every 6–12 months, or sooner if suspension parts, tires, or axles were recently replaced.

3. Can misalignment damage my tires?

Yes—misalignment causes cupping, feathering, shoulder wear, and rapid tread loss, which shortens tire life significantly.

4. Do you align both tractors and trailers?

Yes. We align steer, drive, and trailer axles, including 3-axle and multi-axle configurations.

5. How long does a truck alignment take?

A full professional alignment typically takes 1.5–2 hours, depending on the condition of the suspension and number of axles.

Tire Service FAQs

6. What causes uneven tire wear on a semi-truck?

Uneven wear can be caused by misalignment, incorrect tire pressure, worn suspension parts, or unbalanced tires.

7. How often should truck tires be rotated?

Rotation is recommended every 15,000–25,000 miles, depending on driving conditions and load weight.

8. What can vibration in the steering wheel mean?

This usually indicates tire imbalance, worn suspension parts, or front-end alignment issues.

9. Do you provide roadside tire repair?

Yes—our team offers fast, mobile roadside tire repair for punctures, air loss, bead leaks, and emergency tire issues.

10. Can tire checkups extend tire life?

Absolutely. Routine inspections help detect early wear patterns and prevent expensive blowouts or replacements.

Suspension & Steering FAQs

11. What causes kingpin or bushing wear?

Heavy loads, road impact, lack of lubrication, or natural aging of suspension parts.

12. How do I know if my kingpins need replacement?

Symptoms include loose steering, popping noises, vibration, uneven tire wear, or delayed steering response.

13. What are signs of failing air suspension?

Leaning, sagging, slow leveling, air leaks, rough ride, or inconsistent ride height.

14. Do suspension issues affect alignment?

Yes—worn shocks, bushings, and joints cause repeated misalignment and rapid tire wear.

15. Can bad steering joints be repaired or must they be replaced?

Most worn steering joints need complete replacement for safe, predictable steering performance.

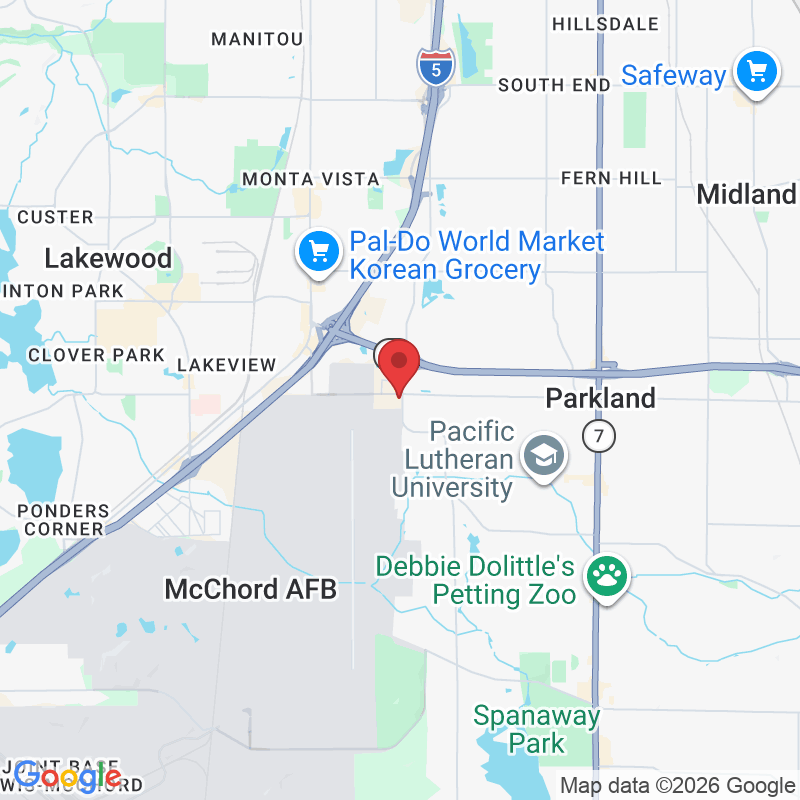

Our Service Area

Contact Us Today

Schedule your appointment today and experience expert truck tire and alignment services!